Synthetic Drawing and Stamping Lubricants

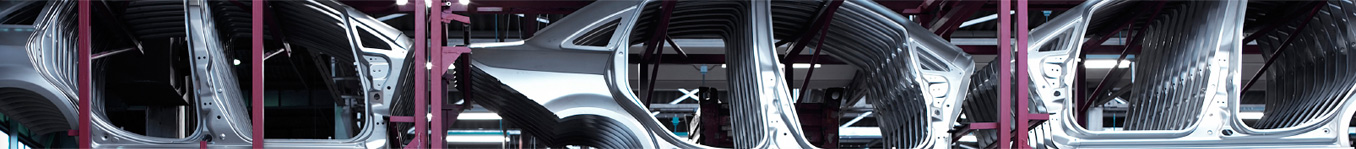

International Chemical Company is extremely proud to manufacture a complete line of synthetic, water-soluble, heavy-duty metalworking lubricants for use in industrial applications. Simply put, synthetic metalworking fluids are a powerful combination of surfactants, boundary lubricants and proprietary additives. These additives provide specific advantages over mineral oil-based metal-forming lubricants because they contain no petroleum byproducts and are environmentally responsible.

International Chemical Company's fully synthetic, non-chlorinated drawing and stamping lubricants and oils exhibit excellent viscosity-to-temperature behavior and perform well within a very wide temperature range, making them perfect for use as high-speed industrial stamping lubricants. These soluble industrial synthetic oils are particularly effective in hard water and contain low-foaming properties for post-washing of manufactured components. The 1599 Series of Synthetic Lubricants are based on a formulation engineered specifically for use in high-pressure steel forming operations such as drawing, stamping, forming, blanking, piercing, perforating, roll forming and continuous welded tube production. They provide the necessary friction-reducing high film strength lubricity required of roll-forming lubricants, preventing wear and galling (cold welding), functioning as flood coolants to the tooling and work pieces to dissipate and prevent heat build-up, and to minimize soil accumulation on the tooling.

Synthetic Lubricants

- IC 1598-C is a heavy-duty full-synthetic lubricant that is formulated specifically to be compatible with yellow metals. In addition to copper and brass, it is compatible with aluminum and carbon steel; a true, all-metal synthetic lubricant for drawing, stamping and metal-forming operations. As with lubricants in the 1599 Series, this fluid provides for smokeless welds, and the residual film provides excellent corrosion protection.

- IC 1599 is the most versatile and heavy-duty of the series of synthetic drawing and stamping oils and lubricants. It is a water-based and fully synthetic metal-forming lubricant recommended for use in operations requiring an extremely heavy-duty formulation that is equal in performance to heavily chlorinated oils (for this application, IC 1599 should be used as received). In some cases, diluted solutions of IC 1599 have performed better due to the cooling characteristics of water and the combination of built-in extreme pressure additives. It is ideally suited as an industrial metal-forming lubricant for any and all operations utilizing carbon steel, stainless steel, galvanized steel, brass and aluminum. The high film strength lubricity reduces friction and provides anti-wear protection for dies and tooling.

- IC 2524 is an all-metal, heavy-duty synthetic lubricant that is formulated to be compatible with, and non-staining to, brass, bronze, and aluminum. It is ideal for operations where these alloys are found in addition to carbon steel, galvanized steel, and stainless steel. For heavy-duty drawing, stamping, and metal-forming, it is used at full strength, but may be diluted with water as necessary for less severe applications.

- IC 2515 is a heavy-duty full-synthetic lubricant that is engineered for use in precision deep drawing and stamping operations utilizing stainless steel alloys. The high film strength lubricity reduces heat and friction, while providing efficient anti-wear protection for dies and tooling. It is formulated to be non-staining and non-corrosive; to be compatible with hard and soft water; provide for smokeless welds; and offer outstanding corrosion protection.

- IC 1599-B is a phosphate-free, moderately-viscous and heavy-duty metal-forming lubricant containing a low percentage of chlorinated fatty acids formulated for high film strength lubricity. Metal-forming lubricants such as this unique, synthetic blend are recommended for industrial applications utilizing carbon steel, galvanized steel, stainless steel and aluminum alloys. It may be applied via all conventional methods and makes for an excellent high-speed stamping lubricant.

- IC 2535 is a heavy-duty, non-chlorinated synthetic lubricant that is compatible with carbide tooling and is formulated to be ideal for use with pre-treatment operations (e.g., acid-based cleaning systems) which process formed parts composed of metals like carbon steel, galvanized steel, stainless steel, brass, and aluminum. The residual film provides smoke-less welds and is free-rinsing, thereby preventing any downstream problems with paint or coating adhesion, while providing rust protection to ferrous metals.

- IC 2521 is the heaviest of the heavy-duty synthetic lubricants. Clean, low-foaming, boron-free and blended with a robust sulfurized EP additive, it is formulated to be effective in severe and extreme drawing, stamping, and metal-forming operations utilizing metals such as carbon and stainless steel. Similarly to all synthetic lubricants, the residual films provide outstanding rust and corrosion protection; offer smokeless welds; and are readily removed in aqueous parts-washing equipment.

Case Studies

IC 1599-B

Synthetic Water-Soluble Lubricant

IC 2524

Synthetic Water-Soluble Lubricant