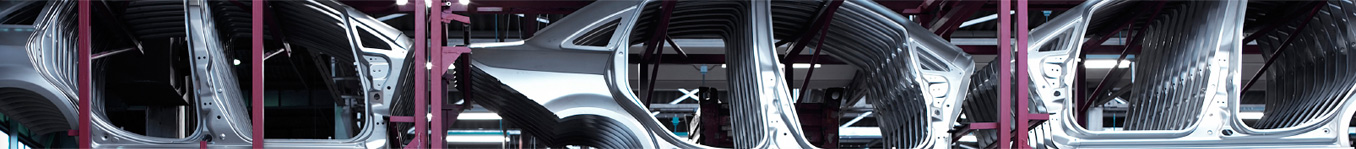

International Chemical Company has been researching, developing and manufacturing metalworking coolants for machining and grinding operations for over 100 years. Our advanced-technology synthetic coolants, semi-synthetic coolants, as well as straight and soluble oils, provide superior detergency, effective rust and corrosion protection, and efficient cutting and flushing characteristics that are second to none. Metalworking coolants for industrial applications ultimately need to be powerful, clean, efficient and long lasting. ICC's metalworking coolants are engineered to fulfill all your needs.

Synthetic Coolants: Mineral oil-free metalworking fluids for industrial machining and grinding operations are gaining popularity among manufacturers. In recent years, ICC has increased investment in painstaking research and development of synthetic technology in an effort to provide equivalent or better metalworking performance versus straight and soluble oils. ICC's synthetic machining and grinding coolants are formulated with non-toxic and non-hazardous components, resulting in metalworking fluids that are highly stable, economical and environmentally responsible. They provide exceptional detergency and exhibit very low-foaming characteristics. For your metal fabrication needs, a synthetic metalworking machining and grinding coolant may be an often overlooked alternative for operations like CNC machining, industrial grinding and metal cutting, where conventional straight or soluble oils may have been historically utilized. Due to the unrelenting diligence of our formulators, ICC's customers receive the ultimate in advanced synthetic metalworking fluid technology.

Semi-Synthetic Coolants: As the old saying goes, a little of something can go a very long way. In the case of semi-synthetic metalworking fluids, that little something is small percentages of premium, hydro-treated, naphthenic mineral oils combined with robust surfactants and highly detergent additives. As a result, ICC's semi-synthetic cutting fluids, thread cutting oils, CNC machine coolants, in addition to turning and thread cutting coolants are expertly formulated to provide metalworking operations with enhanced lubricity, particularly in heavy-duty to severe tapping operations and those which incorporate specific grades of aluminum. Since the introduction of semi-synthetic metalworking coolants many years ago, these industrial cutting fluids have compiled an inconsistent service record and earned a reputation for performing well, but just not well enough. However, with the advent of new synthetic technology, ICC is proud to manufacture the finest semi-synthetic metalworking fluids in the industry.

Straight Oils: Ever-quickening advances in chemical engineering and metallurgy have positively impacted metal manufacturing (e.g. the increased usage of lightweight alloys and composite materials). Concurrently, the need for straight oil machining and grinding coolants is receding, however gradually. But there still exists those severe and extreme metalworking operations where only straight oil metal cutting fluids will suffice. ICC's straight oil tapping, thread cutting, turning, milling, and grinding coolants help you make these types of metalworking operations work, even in the most brutal conditions. Featuring both excellent wetting and lubricating properties for both tooling and work pieces, ICC's straight oils can make the most challenging metalworking operations succeed.

Soluble Oils: The most commonly utilized metalworking fluids—water-soluble oil coolants—provide excellent performance in a variety of grinding, CNC machining and cutting operations. These water-soluble oils form remarkably strong and stable emulsions, even in hard water. ICC emphasizes the incorporation of advanced-technology additives in our water-soluble oil coolants. Through the potent combination of select bio-resistant components with powerful extreme pressure additives and unique emulsion packages, ICC's water-soluble oil coolants are much stronger and cleaner, as well as more efficient, longer lasting and vastly more economical than other water-soluble oils available today.